Our machines:

- 1 x Fanuc ArcMate 100iC

- 4 x Fanuc ArcMate 100iC/6L

- 1 x Fanuc ArcMate 120iC/12L

- 2 x Fanuc M710iC/70

- 2 x Fanuc R2000iB/165F

- 1 x Fanuc S420iW

Currently there are 11 robots working at our company.

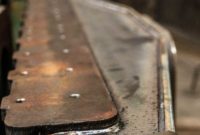

Welding robots are perfect for high quantity jobs with high quality demand. They enable cost reduction, especially in case of repetable parts or heavy parts with big sized welds that need position change during welding.

There are two robot lines with 4 robot each in our company, that have fully automated process of loading material into the fixtures and unloading welded parts from the fixtures followed by fully automated grinding process. Full automatisation allowed the reduction of production time of each part and significant quality gain and repetability of welds and grinds unachievable for manual welding and grinding.

There are also two welding cells with robots on rails. Smaller one has 5 meter rail and two 1-axis positioners, the bigger one has 9 meter rail and two 2-axis positioners with maximum payload of 1,5 ton.